Creating ATE Switching Subsystems: 3 Approaches for Successful Implementation

Engineering departments face challenging macroeconomic forces like supply chain issues and price increases. To mitigate time-to-market and budget risks, test engineers must plan test systems earlier – often in tandem with product design plans. This means that during the early product design phase, test engineers must also design test systems, ensure those systems will be deployable with available components, and confirm any outsourced test system design or engineering resources required.

Switching subsystems are at the center of most automated test systems (ATEs). By defining requirements for these switching subsystems early, engineers have the flexibility to select the ideal hardware components and software tools, ultimately building a customized modular platform that will meet the demands of the current product and scale with product growth or be reused for future iterations.

Test engineers take one of three approaches for the successful design, build, and deployment of efficient, effective switching subsystems:

- COTS-based Product Selection

- COTS Products + Guidance and/or Support

- Outsourced Build

This article will overview each approach and the careful considerations test engineers must make to seamlessly move products from R&D to production test with modular switching solutions that are fit to spec, seamless to integrate, and built to last.

Before beginning, consider the following:

- Are you modifying an existing test system or creating a new one?

- Will the system be based on industry standards such as PXI or LXI?

- What software will be used to program and control the system?

- What specifications will you be testing?

- What is the maximum voltage, current and frequency your system must manage?

- Do you need to accommodate any legacy hardware or software technologies?

- Is this test for new technology or existing products?

- Will this system need to scale to accommodate expanded requirements in the future?

- Will the system potentially be reused to test additional products?

- Is there a strategy for maintaining the system?

Approach #1: COTS-based Product Selection

A COTS-based approach is appropriate for a project with well-defined requirements, and an in-house team experienced in selecting and deploying switching instrumentation.

This process typically begins by exploring the websites of switching vendors to find products that meet test system design requirements.

Critical factors to consider when taking a COTS-based approach include:

- Managing Obsolescence – ensure test systems that need to be maintained for more than ten years (common in aerospace/defense applications) have an obsolescence plan

- Navigating Internal Resources – ensure internal teams have the bandwidth and skillset to build and deploy an effective, future-proof switching system

- Integration with a Complete Test System – ensure hardware and software compatibility for integration with other existing or planned elements of the test system

- Ease of Acquisition and Maintenance – ensure selected switching hardware is available and will be maintainable for the entire product lifecycle

For an off-the-shelf approach, Pickering offers a vast range of industry-standard modular switching products, selectable via an easy-to-use Product Selector. Configuring powerful and flexible LXI microwave switching products has never been easier than with our Microwave Switch Design Tool. This free online software greatly simplifies the configuration of your flexible LXI RF & microwave switching and relay systems for signal routingStandard interconnect products are available for all switching modules to streamline integration, and the design of custom cabling can be significantly simplified by Pickering’s free-to-use web-based Cable Design Tool. Customers can also use Pickering simulation tools to design test applications and verify test system compatibility before purchasing components. Additionally, our Knowledgebase, datasheets, manuals, 3D models, and PXI and LXI platform overviews support customers’ product selection while flexible software drivers, automated switch routing software, and diagnostic test tools simplify and accelerate integration and maintenance.

Though some product companies begin with a COTS-based approach, they’ll often shift to Approach #2 when they need further consultation around finding the right solutions for obsolescence, compatibility, hardware/software support and future flexibility considerations.

Use our product selection tool to find the right switching components for your system: https://www.pickeringtest.com/products

Approach #2: Products + Guidance and/or Support

This approach is ideal for companies that have yet to decide what products will best meet their test system design needs or lack internal resources (time, workforce, or experience).

This process begins when you reach out to a switching vendor or system integrator with an overview, schematic or even just a basic sketch of what you want to achieve, and the expert team can advise on different hardware and software products to optimally satisfy your system needs.

Seeking outside guidance is typically interactive and comprehensive, covering hardware, software, interconnect, integration and sustainment. In collaboration with the customer, the switching partner will design an ideal solution with products that meet all requirements – including technical specifications, budgets, and timelines. Selecting industry-standard, modular hardware throughout this process eases integration and ensures future-proof scalability, flexibility and long-term sustainment.

Consider asking the following of your switching system provider:

- How compatible are your products with other vendors’ hardware and software?

- Does the complete switching system meet or ideally exceed the required system specifications?

- Do you have the software drivers and application support that I will need?

- Can you help with cabling and custom interconnect? If not, where can I turn for support?

- What if I experience system failure after deployment?

- Is this solution readily scalable in the future?

- Will I be able to adapt it to support different applications easily?

- What are the lead times on these products?

- How long will these products be supported?

- Do you have any tools and expert support to speed up my program generation?

Pickering works with clients when they have some internal resources but need to supplement these with outside technology or expertise.

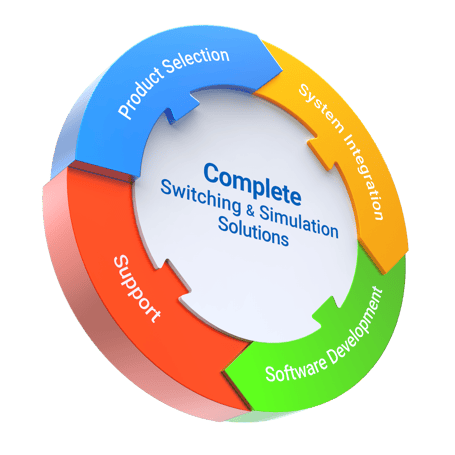

By using this visualization wheel, we can help identify how to help customers at various stages of the development process.

Even for customers selecting the switching hardware themselves, Pickering experts can create custom simulation environments to speed software development, provide automated signal routing software that can cut development time in half, and supply standard and custom cables to integrate the switching system into the larger automated test equipment (ATE).

Read more about how one customer consulted with Pickering to find the best switching products, software, and interconnect: https://www.pickeringtest.com/resources/articles-white-papers/success-story-pickerings-pxi-lxi-switching-used-in-hass-testing

Approach #3: Outsourced Build

This approach fits companies looking to contract an expert partner to plan, design and build the full ATE switching subsystem. Outsourcing is ideal for companies lacking the time and resources to take the do-it-yourself approach. Even when a company builds and manages its own ATE, switching systems can have such intricate requirements that it’s easier to outsource the switching subsystem and procure a solution that will last for 10+ years rather than acquire the system design domain knowledge internally.

Outsourcing is particularly helpful when timelines are critical, and you need a switching solution that you can receive, integrate, and have up and running quickly or when there’s a possibility of build-to-print systems in the future as your product scales. An outsourced provider can create a switching subsystem with reproducibility in mind to future-proof your operations.

In this process, a switching partner or system integrator can not only design and build the subsystem but start from the beginning to help define requirements – and then provide all of the necessary tools to streamline integration, deployment and ease sustainment and long-term system maintenance.

When Pickering takes on creating ATE switching subsystems, clients can take advantage of many options based on product lifecycle goals:

- Quicker timelines

- Switching systems tailored to the test system specifications for repeatable results

- Future-proof, flexible and scalable designs

- Mating system interconnect

- Supplied software drivers

- Software support for all major programming languages, including NI software

- Graphical soft-front panel for manual control and monitoring

- End-to-end switching simulation

- End-to-end switch routing software

- Proprietary diagnostic test tools

- Fully documented components, tested to ensure performance repeatability in subsequent builds/orders

- Worldwide technical hardware and software support infrastructure, including cost-effective RMA repair service.

- 3-year system warranties

- Up to 20-year ongoing support, including free software updates

This approach streamlines the development and deployment of high-performance electronic test and verification systems. Companies can scale or repurpose system components in the future as needs, objectives, or requirements change while remaining as timely and cost-efficient as possible.

See how Pickering created a complete, flexible, future-proof avionics test system for a mission-critical aerospace application: https://www.pickeringtest.com/resources/success-stories/success-story-flexible-future-proof-avionics-test-system

Conclusion

As technology innovation continues, intricate switching systems are at the core of automated test equipment. Depending on budgets, timelines, internal expertise, system compatibility demands, and anticipated product development lifecycles, there is a range of solutions for developing switching systems – from engineering a solution in-house with COTS products to completely outsourcing a subsystem.

Learn more about designing and building a standardized ATE switching subsystem for a successful test program in this white paper.