Considerations for Building or Buying an Automated Test System

Automated test equipment (ATE). is an integral part of modern manufacturing. ATE systems are used to test products during and after production and play a vital role in quality control. These systems can be complex and often require specialized switching subsystems. Creating these subsystems can be a challenge. Organizations can build these systems in-house or work with a partner to outsource them.

First, it's important to understand the requirements of the subsystem. What types of signals will it be required to switch, such as DC, AC, RF, microwave, differential/single-ended, or optical? What is the maximum switching speed? What is the maximum voltage and current? Once the requirements are understood, it's possible to select the appropriate components.

First, it's important to understand the requirements of the subsystem. What types of signals will it be required to switch, such as DC, AC, RF, microwave, differential/single-ended, or optical? What is the maximum switching speed? What is the maximum voltage and current? Once the requirements are understood, it's possible to select the appropriate components.

Next, the subsystem must be designed. This step includes creating a schematic diagram and selecting the right platform. Think about the signals that will be used and the order in which they will be switched.

Finally, the subsystem must be built and tested. This step includes assembling the components and testing the subsystem to ensure it meets the requirements.

Let's discuss three important factors to consider when building a switching subsystem or outsourcing it: cost, scalability, and support. Not taking these things into account will likely have negative consequences on the longevity of your system.

1. The Total Cost of a Switching and Simulation System

Most engineers only consider the up-front cost of developing an electronic test system, evaluating only what their current budget allows. But it's important to consider the cost to build and maintain your test system over time, and which solution would be most cost-effective – to build or to buy.

Take a look at your test system requirements. Building and using your internal resources could be more cost-effective if you have significant custom needs. However, if your core competency is not test and verification systems, you may not want to waste your time, energy, and resources to develop the system.

In most cases, outsourcing and working with a partner to develop commercial off-the-shelf (COTS) products makes more sense. A partner can create a test system that best supports your price point over the system's longevity. If you need to develop multiple systems, a COTS-based solution ensures you're creating a repeatable system. COTS products are typically supported over a longer duration and are easier to replace over time.

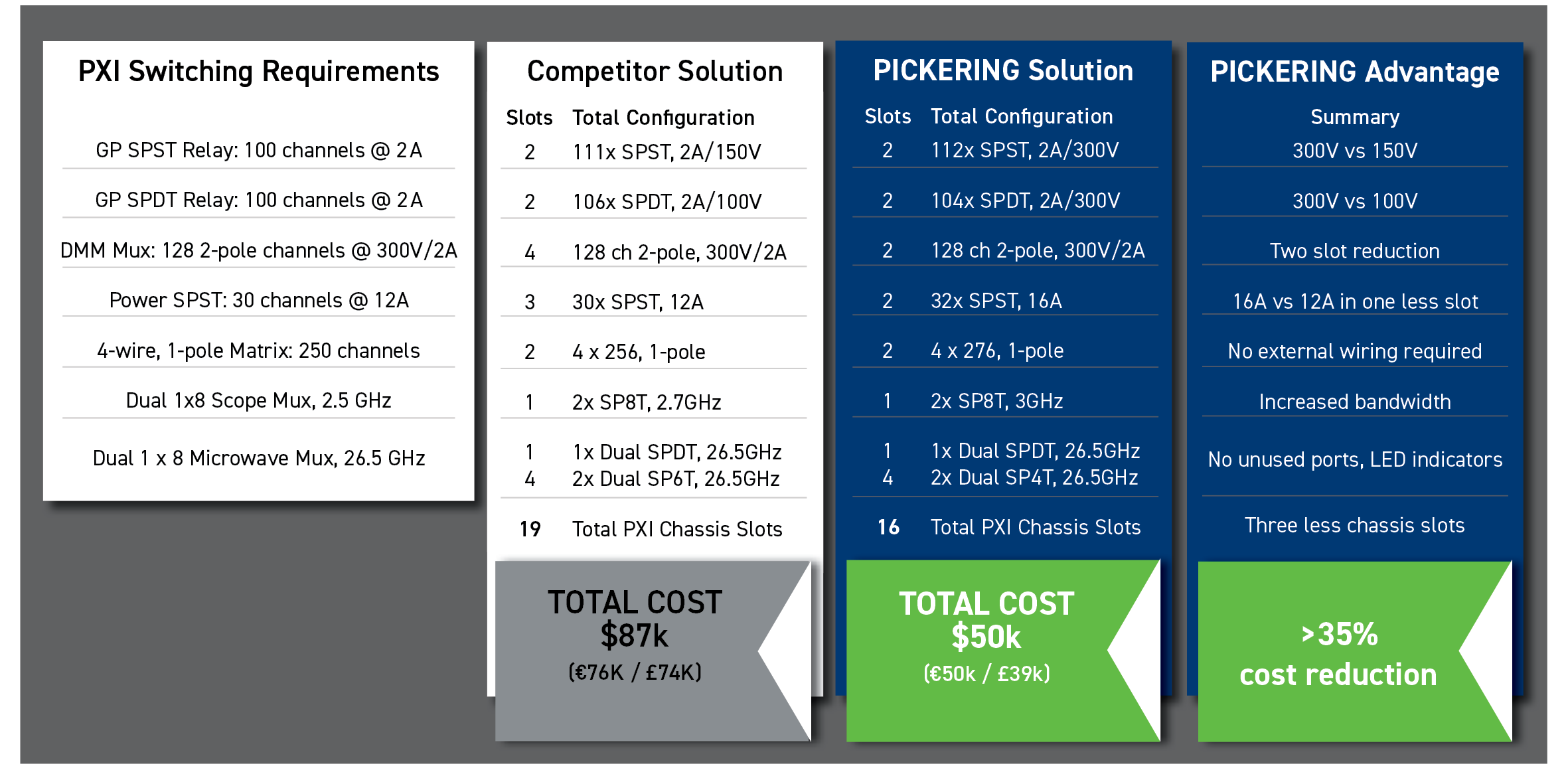

Comparing vendors for COTS products is an important step to optimize your up-front and long-term maintenance costs. Below is an example of how Pickering's solutions compare to our most direct competitor.

The chart above demonstrates that within COTS-based solutions, there are options. Engineers must define their requirements and evaluate different outsourced partners and their associated costs.

Cost Summary: If you have unusual requirements, such as very high currents or power requirements, tight or irregularly shaped physical space restrictions, or extreme operating environmental needs, it could be cost-effective to build. But in most cases, buying COTS products is the most efficient solution.

2. Building a Switching and Simulation System that Scales

Whether you want to build or buy, modularity is the key to scaling your system as your operations grow. Modularity allows you to scale rather than design a new system as your needs change. If you don't design for the future, you may have to develop another new test system for additional products.

Consider the benefits of standardizing on a common platform such as PXI or LXI:

- You won’t be tied to a specific vendor because the system is not vendor-specific

- Lower cost because key components (power, user interface, etc.) are shared among modular components

- The standard can be enhanced and maintained since there’s an expert technical committee behind it

Custom solutions (whether built in-house or outsourced) are difficult to scale because those solutions weren't developed in additional quantities. By outsourcing and using COTS products, more of the same product can be purchased over time, thus allowing you to scale your test system easily.

Scalability Summary: In summary, scalability and designing for the future are something to consider when deciding whether to build or buy. Building a system is better if you won't be scaling in the future, while buying a COTS-based system brings benefits when your product line grows.

3. Supporting your Switching and Simulation System for the Long Run

Encountering a problem with a test system can halt your production line or critical product testing procedures, costing time and money. Having a support team available is important whether you're building or buying.

When testing a product that will often evolve, resulting in a new test system each time, you may not need much ongoing support and can build your system in-house. But, if your product will need long-term support due to regulatory compliance demands, such as those in defense, it's beneficial to have a strong team of dedicated experts, as components can become obsolete over time.

For some industries, validating the test system is a lengthy process. And, if you choose to design in-house, oftentimes the documentation process isn't correct and validating becomes challenging. If the documentation process isn't correct, it can be difficult to support your test system in the future.

Support Summary: Planning for the future allows you to anticipate needs and be prepared when components need to be fixed or scaled. As you rebuild, a dedicated support team can be the difference between shutting down the production line temporarily or permanently.

Pickering’s Approach to Cost-Effective, Scalable, Maintainable Switching and Simulation Systems

With more than 50 years of experience in switching for automated test, we have a broad range of products and services that'll work with your budget, scalability, and support needs. And when our COTS solutions don't match your requirements, we'll work with you to plan, design, or build the full switching subsystem.

We design for:

- Repeatability: to be easily manufactured and produce accurate, reliable results

- Maintainability: to be serviced efficiently and last 10+ years

- Scalability: to grow with product lines and functionality

- Flexibility: to be reused for future applications

You can scale or repurpose system components in the future as objectives or requirements change while remaining as timely and cost-efficient as possible. Our technical staff can address any hardware or software problems you may encounter. We have multiple offices worldwide and provide access to support engineers with many years of experience in functional test.