Relay 101: The Different Types of Relays and How they Operate

When selecting a switching system, the relays used in the switching modules are either mechanical or solid-state in construction. Each has unique benefits and failure modes. Because of their infinite virtual life and fast switching speed, solid-state relays are generally best suited for high-speed scanning data acquisition applications. However, because of the relatively high DC path resistance, insertion losses in RF applications, and off-state current leakage of these relays, mechanical relays are much more commonly used for general purpose switching applications. This blog post will concentrate on these types of switches.

Unlike solid-state relays, mechanical relays have moving parts that will wear out over time, leading to failure. The manufacturer’s life expectancy specification provides information on when you can expect relays to wear out mechanically. Essentially, this specification is the number of times a relay can operate under specific load conditions. The life expectancy can vary considerably depending on the load being switched. It is also important to note that operating outside of the specified range will lead to accelerated wear and premature failure.

Types of Mechanical Relays

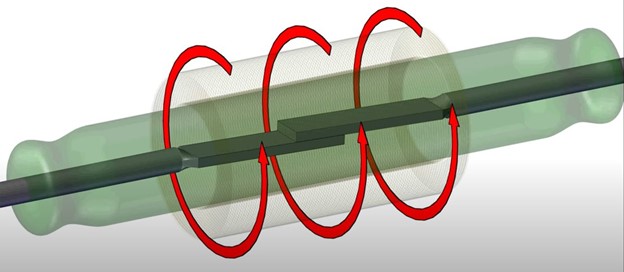

There are two types of mechanical relays: reed relays and electromechanical relays (EMRs). Both have metal contacts that engage when their control lines are energized, but there are critical differences in their construction. Reed relays have hermetically sealed contacts in a glass tube, surrounded by a wound operating coil. As current flows through the coil, a magnetic force pushes the contacts together, forming the connection path. Removing the current through the coil separates the contacts. There are few moving parts, which means there are fewer points for failure when compared to electromechanical relays.

Reed Relay. As current flows through the coil, a magnetic force pushes the contacts together, forming the connection path

Reed Relay. As current flows through the coil, a magnetic force pushes the contacts together, forming the connection path

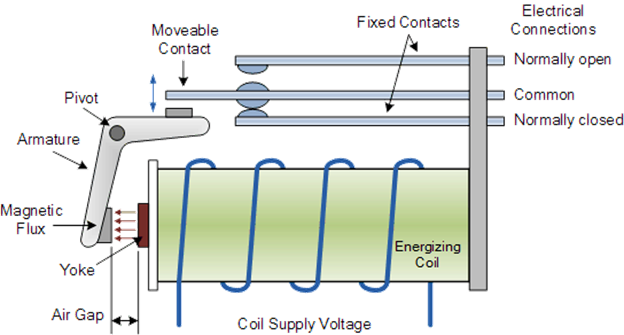

In electromechanical relays, there are more moving parts. The EMR contacts are connected to armatures which move on a pivot point connected to a spring. Energizing the operating coil creates a magnetic field that moves the armatures and engages the contacts. Whether a reed or EMR is the suitable relay to use depends on the application. Since the reed contacts are hermetically sealed, they are less prone to oxidation and contamination, leading to more consistent switching characteristics and are well-suited for low-level switching applications up to about 2 Amps.

Electromechanical Relay (EMR). This has more moving parts than the Reed Relay.

EMRs, on the other hand, have contacts with larger surface areas which make them better suited for higher power switching. They are often enclosed in plastic packages that provide a certain amount of protection from the environment. Still, the contacts over time are exposed to external pollutants, outgassing from the plastic body, and oxygen and sulfur ingress. All of this can lead to unstable contact resistance, which presents issues for low-level applications.

To facilitate switching at low levels, the contacts are typically plated in gold to resist oxidation. However, when used to hot switch, the gold plating will wear off over time, and the contacts become compromised. This is why EMR specifications typically include a minimum switched load specification.

In general, instrument grade reed relays have the most extended mechanical life because they have fewer moving parts and do not require a minimum switched load to meet specifications.

If you need help finding the correct reed relay for your test system, try our Reed Relay Selector tool.

Relays and Switching

When a relay is either opened or closed while carrying a signal, we say that the relay is “hot switching.” Hot switching is often necessary for a test application, but it also results in the most wear and tear on the relay. Relays that hot switch signals are subject to voltage spikes and generally run hotter. These conditions will lead to early-life failures. Hot switching at 50% maximum load capacity can reduce relay life by up to three orders of magnitude. For reed relays, typical operating life under light load can be up to 5 billion operations but only 5 million operations at a heavy load.

It is not always obvious how much voltage or current a relay is hot switching; for example, if a relay connects a low-impedance source to a high-impedance load, you would expect the switched current to be relatively low. However, if the cabling or load has significant parasitic capacitance, there may be a high-surge current through the relay when it closes as the source charges the capacitor.

A relay may also experience a high surge current when it connects a source to a capacitive load carrying a charge from a previous state. This might occur, for example, when a switching system reverses the polarity on a Unit Under Test (UUT) or if a previous operation has left a charge on a high impedance load. For this reason, some cable test systems provide a way to discharge any residual charge on the cable assemblies before actuating the relays. However, as mentioned earlier, the specifications for switching modules typically only define a maximum hot switch voltage/current/power when the module is connected to a resistive load. So it should be noted that if long cables or other capacitive loads are attached, the rating may be affected.

In short, having a solid understanding of the use case is necessary when trying to predict the life expectancy of your automated switching system that extends beyond the manufacturer’s specifications.

When to Replace RelaysIn an ideal world, compromised relays can be identified before they fail and shut down production. The clearest indicator that a relay may be reaching its end of life is by the number of times it has been cycled. Once a relay is getting close to its specified maximum operation count, it might be time to replace it. Some switch products offer the ability to count the number of times each relay has been cycled, which is called a relay odometer. This number can then indicate that a specific relay is nearing its end of life and should be replaced.

Prematurely replacing relays based purely on cycle count can also induce more faults through component stress during service (particularly surface-mounted devices). Repeated intervention may render a perfect switching system unusable. Therefore, we recommend that production engineers replace relays that have demonstrated failures. In other words, “if it’s not broke, don’t fix it,” and instead focus on creating a more efficient diagnosis and repair process.

The challenge with waiting for a failure to occur before fixing it is that failures often occur at inopportune times, often in the middle of high production demand. Running system self-tests at regular intervals is one way to minimize impact to production, as it is not unusual for a switch failure to occur during production runs. When this occurs, pressure is on efficiently diagnosing the root cause and returning the system to operational status.

Self-test routines check all components in the signal path, so they will verify the switches and the interconnect system, including a mass interconnect receiver if fitted. Production self-tests are designed to get a failed system up and running quickly and usually only isolate a failure to a component in the system that can be easily replaced on the production line — a line-replaceable unit.

Conclusion

Now that you have insight into the selection and support of relays, you are one step closer to designing a successful ATS. To ensure that it is fast, accurate, and reliable, the switching portion requires careful selection as the wrong relay types can fail prematurely or provide inaccurate measurements. And, when possible, maintain an inventory of spare relays for critical switching modules.

For more information about switching, check out our Switchmate eBook and watch the on-demand webinar: Maximizing Reliability in Signal Switching.